lippert slide-out manual override

Lippert Slide-Out Systems are widely used in RVs‚ offering smooth room expansion. They feature electric motors and manual override options for reliable operation. Proper maintenance ensures efficiency.

1.1 Overview of Lippert Slide-Out Technology

Lippert Slide-Out Technology enhances RV living by providing smooth‚ electric-powered room expansion. The system uses motors and gears to extend or retract rooms. It offers both hydraulic and electric options‚ ensuring reliability. A key feature is the manual override‚ enabling operation during power failures. Users can engage a crank or drill to move slides manually. The technology includes in-wall and through-frame systems‚ designed for durability. Regular maintenance‚ like lubricating rails‚ is essential for optimal performance. This innovation improves space utilization and comfort‚ making it a staple in modern RV designs. Proper synchronization and alignment ensure seamless functionality and prevent leaks.

1.2 Importance of Manual Override in Slide-Out Systems

The manual override in Lippert Slide-Out Systems is essential for emergencies or power failures. It allows users to control the slide-outs without electricity‚ ensuring functionality when needed most. This feature prevents system malfunctions from causing operational shutdowns. By enabling manual operation‚ it provides a reliable backup solution‚ maintaining RV comfort and safety. Proper use of the manual override prevents misalignment and potential damage. It is crucial for maintaining control during unexpected issues‚ ensuring rooms can be extended or retracted safely. This redundancy is a key advantage of Lippert systems‚ offering peace of mind for RV owners. Regular maintenance ensures smooth operation.

Understanding the Manual Override Process

The manual override process involves locating the mechanism‚ disengaging the motor‚ and manually operating the slide-out. It ensures functionality during power failures or motor issues.

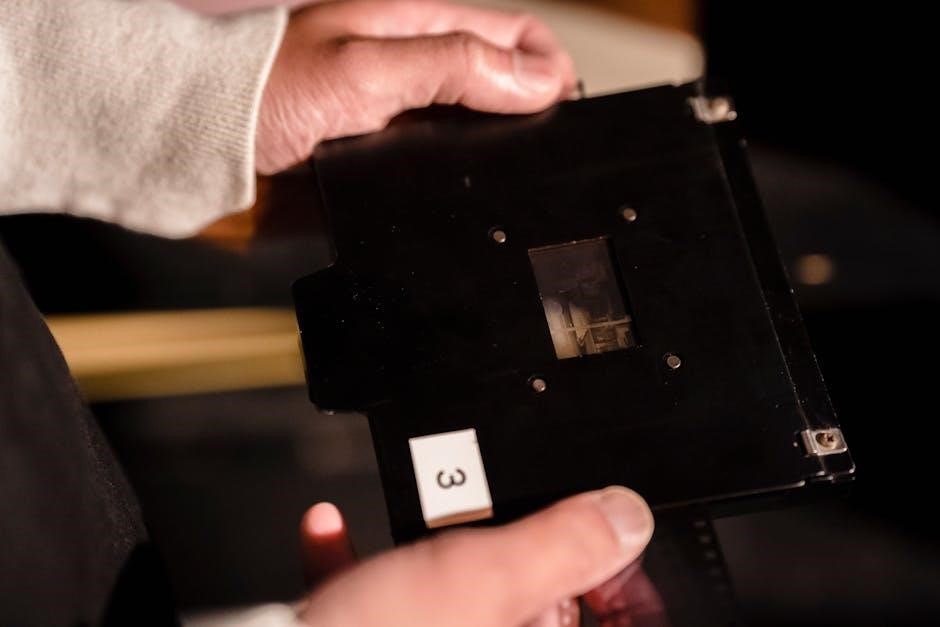

2.1 Locating the Manual Override Mechanism

The manual override mechanism is typically found near the slide-out motor‚ often under the bed platform or behind an access panel. It may require removing screws or panels to access. Some systems use a through-frame crank‚ while others have an in-frame design. Ensure you identify the correct location and type of mechanism to avoid damage. Always consult the user manual or manufacturer’s guide for specific instructions tailored to your Lippert system model. Proper location ensures safe and effective manual operation during emergencies.

2.2 Steps to Disengage the Electric Motor

To disengage the electric motor‚ first ensure the slide-out is stationary. Locate the electronic control box and switch off the power supply. Hold the slide-out switch for 5-10 seconds until the motor stops completely. This step may need to be repeated to fully disengage. Once the motor is disengaged‚ you can safely access the manual override mechanism. Always ensure the motor is fully stopped before proceeding with manual operation to avoid damage or injury. This process ensures the system is ready for manual control when needed.

2.3 Manually Operating the Slide-Out System

To manually operate the slide-out system‚ locate the manual crank or override mechanism‚ typically found near the motor. Insert a 1/4 hex socket into the drive motor’s socket and use a drill or wrench to turn it clockwise or counterclockwise‚ depending on the direction needed. Ensure the motor is fully disengaged before starting. Slowly crank the slide-out while checking for obstructions; If resistance is felt‚ stop and inspect for misalignment or debris. Manual operation should only be used when the electric motor is disengaged‚ as forced movement can damage the system. Always follow safety guidelines to avoid injury.

2.4 Re-engaging the Electric Motor After Manual Operation

After manually operating the slide-out‚ ensure it is fully extended or retracted and properly aligned. Turn the power to the system back on at the breaker or control panel. Press and hold the slide-out switch in the desired direction until the motor engages. You may need to reset the system by holding the switch for 5-10 seconds to resynchronize the motors. If the motor does not engage‚ check for error codes on the controller‚ such as low voltage indicators. Ensure all moving parts are clear of obstructions before re-engaging the motor. Proper alignment is crucial to avoid damage.

Common Issues with Lippert Slide-Out Systems

Common issues include electrical malfunctions‚ motor synchronization problems‚ and alignment gaps. These can cause incomplete extension or retraction‚ leaving noticeable spaces. Regular maintenance helps prevent these issues.

3.1 Troubleshooting Electrical Malfunctions

Electrical malfunctions in Lippert slide-outs often stem from low voltage or faulty wiring. Users may encounter error codes like code 3‚ indicating voltage issues. First‚ ensure the RV’s power supply is stable. Check for loose connections in the control box and motors. If the motor doesn’t respond‚ bypassing the control box temporarily can help diagnose the problem. Resetting the system by holding the switch until motors stop can sometimes resolve synchronization issues. Always refer to the user manual for specific guidance‚ and consult Lippert support if problems persist.

3.2 Resynchronizing the Slide-Out Motors

Resynchronizing Lippert slide-out motors is essential after manual operation or electrical issues. Start by fully retracting the slide and holding the switch until the motor stops. Locate the reset button on the control box and press it six times. This process may need to be repeated several times to resynchronize the system. If error codes appear‚ check the manual for specific instructions. Ensure the slide is properly aligned before attempting to extend it again. If issues persist‚ consult the user manual or contact Lippert support for further assistance.

3.3 Adjusting Slide-Out Alignment for Proper Sealing

Proper alignment of the slide-out system is crucial for ensuring a tight seal and preventing leaks. Start by fully retracting the slide and inspecting the alignment of the room seals. If misaligned‚ gently adjust the slide by loosening the mounting bolts and shifting it into the correct position. Once aligned‚ tighten the bolts securely. Test the seal by extending and retracting the slide several times. If gaps persist‚ check for worn-out seals or obstructions. Proper alignment ensures optimal performance and prevents water intrusion during transit or inclement weather.

Maintenance Tips for Lippert Slide-Out Systems

Regular maintenance ensures smooth operation. Lubricate slide rails‚ clean mechanisms‚ and inspect for wear. Addressing issues promptly prevents costly repairs and extends system longevity.

4.1 Lubricating the Slide-Out Rails

Lubricating the slide-out rails is essential for smooth operation. Apply a silicone-based spray or grease to the rails and moving parts. This reduces friction and prevents rust‚ ensuring the slide-out moves effortlessly. Regular lubrication‚ especially after cleaning‚ helps maintain efficiency and longevity of the system. Avoid using household oils‚ as they may attract dirt. Proper lubrication prevents mechanical issues and ensures the slide-out operates quietly and reliably over time.

4.2 Cleaning and inspecting the Slide-Out Mechanism

4.2 Cleaning and Inspecting the Slide-Out Mechanism

Cleaning and inspecting the slide-out mechanism is crucial for optimal performance. Remove dirt and debris using a soft brush or cloth. Check for wear and tear on rails and gears. Inspect for corrosion or rust‚ addressing it promptly. Lubricate moving parts after cleaning. Ensure the electronic control box and connections are free from dust. Regular inspection helps identify issues early‚ preventing malfunctions. Cleaning ensures smooth operation and extends the lifespan of the system. Always refer to the Lippert manual for specific cleaning recommendations tailored to your model.

4.3 Checking for Wear and Tear on Moving Parts

Regularly inspect the slide-out mechanism for signs of wear and tear. Check the gears‚ rollers‚ and seals for damage or excessive wear. Look for misalignment or corrosion on the rails. Inspect the hydraulic or electric components for leaks or damage. Ensure all bolts and fasteners are secure. Lubricate moving parts to prevent friction and corrosion. Address any issues promptly to avoid system failure. Pay attention to gaps or uneven movement‚ as these indicate potential problems. Regular maintenance ensures smooth operation and prevents costly repairs. Always refer to the Lippert manual for specific inspection guidelines tailored to your slide-out model.

Safety Precautions and Best Practices

Always ensure the RV is on level ground before operating slide-outs. Never manually override without disconnecting power to avoid injury. Keep children and pets away during operation. Use recommended tools and follow the manual instructions precisely. Wear protective gear when performing manual overrides. Avoid overloading the slide-out beyond its capacity. Regularly inspect and maintain the system to prevent malfunctions. Ensure all users understand the system’s operation and safety guidelines before use.

5.1 Safety Measures When Manually Operating the Slide-Out

When manually operating the slide-out‚ ensure the RV is stationary and on level ground. Turn off the engine and engage the parking brake. Disconnect the power supply to the motor to prevent accidental activation. Always use the correct tools‚ such as the provided crank or a compatible wrench‚ to avoid damaging the mechanism. Never allow children or pets near the slide-out during manual operation. Wear protective gloves and eyewear to safeguard against potential hazards. Ensure proper alignment and balance to prevent the slide-out from binding or falling. Always follow the manufacturer’s instructions for manual override procedures to ensure safety and system integrity.

5.2 Understanding the Limitations of Manual Override

The manual override feature on Lippert slide-out systems is designed for temporary use and should not be relied upon as a permanent solution. It may not fully extend or retract the slide-out‚ potentially leaving gaps or misalignments. Frequent manual operation can strain the system and lead to mechanical wear. Additionally‚ improper use of the override mechanism may cause damage to the motor or rails. Always consult the user manual for proper techniques and avoid exceeding the system’s capabilities. If issues persist‚ contact Lippert support for professional assistance to ensure long-term functionality and safety.

5.3 Securing the Slide-Out During Transit

Properly securing the slide-out during transit is crucial to prevent damage and ensure safety. Always ensure the slide-out is fully retracted and aligned before moving the RV. Use the manual override to confirm it is securely locked in place if the electric motor fails. Check all mechanical locks and alignment pins to ensure they are engaged. Inspect the slide-out mechanism for any wear or obstructions that could affect its stability. Refer to the user manual for specific securing procedures. Failure to secure the slide-out properly can lead to damage during transit‚ posing safety risks and potentially causing costly repairs.

Additional Resources and References

Refer to the Lippert Slide-Out User Manual for detailed instructions. Additional guides include troubleshooting videos and forums. Contact Lippert support for technical assistance and replacement parts.

6.1 Lippert Slide-Out User Manual Guide

The Lippert Slide-Out User Manual provides comprehensive instructions for installation‚ operation‚ and maintenance. It includes detailed diagrams and troubleshooting guides. Key sections cover manual override procedures‚ error code interpretations‚ and synchronization steps. Tips for lubricating rails and adjusting alignment are also highlighted. Users can find specific instructions for disengaging motors and manually operating slides. The manual emphasizes safety precautions and best practices. Refer to the index for quick access to topics like slide-out maintenance and repair. This guide is essential for understanding and resolving common issues with Lippert systems.

6.2 Recommended Tools for Manual Override

For manually overriding Lippert slide-outs‚ essential tools include a 1/4″ hex socket‚ a drill with a hex bit‚ and an Allen wrench set. Lubricants like silicone spray are recommended for maintaining smooth operation. Ensure you have a multimeter for diagnosing electrical issues and a torque wrench for proper adjustments. Always refer to the user manual for specific tool requirements. Using the correct tools prevents damage and ensures safe operation. Keep these tools accessible to address unexpected issues efficiently and maintain your slide-out system’s performance.

6.3 Contact Information for Lippert Support

For assistance with Lippert slide-out systems‚ contact their customer support team. Phone support is available at 1-800-798-9814‚ Monday through Friday‚ 8 AM to 5 PM EST. Visit their official website at www.lippertcomponents.com for detailed resources and manuals. You can also submit inquiries via their online contact form. Lippert support specialists are equipped to help with troubleshooting‚ repairs‚ and maintenance. Ensure to have your system model and serial number ready for faster assistance. Reach out to resolve issues like manual override malfunctions or synchronization problems effectively.