svz 18 maintenance manual

The SVZ 18 maintenance manual is a comprehensive guide designed to ensure optimal performance and longevity of the unit. It includes detailed troubleshooting tips, safety guidelines, and technical specifications, making it an essential resource for users. The manual is user-friendly and provides clear instructions for installation, maintenance, and repair, helping to maximize efficiency and reliability while minimizing downtime.

Overview of the SVZ 18 Model

The SVZ 18 model is a high-efficiency air conditioning unit designed for residential and light commercial use. It operates on 208/230V, 60Hz power supply, offering cooling and heating capacities of 18,000 BTU/h and 19,000 BTU/h, respectively. The unit features multi-position airflow, allowing installation in vertical, horizontal, or downflow configurations. With external static pressure options of 75Pa, 125Pa, and 200Pa, it ensures flexible installation in various spaces. The model is part of Mitsubishi Electric’s M-Series, known for energy efficiency and quiet operation, making it suitable for diverse indoor environments. Its compact design and advanced technology provide reliable performance and comfort.

Importance of Regular Maintenance

Regular maintenance is crucial for ensuring the SVZ 18 operates efficiently and effectively. Proper upkeep prevents system malfunctions, extends equipment lifespan, and maintains optimal performance. Cleaning air filters and inspecting components prevents dust buildup and ensures airflow efficiency. Regular maintenance also reduces energy consumption and lowers utility bills. It helps in detecting potential issues early, avoiding costly repairs. Additionally, maintaining the unit ensures compliance with environmental standards and safety protocols. Regular maintenance is essential for preserving the unit’s warranty and ensuring reliable operation throughout its lifespan. By following the manual’s guidelines, users can maintain their SVZ 18’s peak performance and safety standards.

Structure and Content of the Manual

The SVZ 18 maintenance manual is organized into clear sections for easy navigation. It begins with an introduction and overview, followed by safety precautions and detailed maintenance requirements. The manual includes troubleshooting guides, repair tips, and environmental disposal guidelines. Each section is designed to provide specific information, ensuring users can quickly locate relevant procedures. The content is comprehensive, covering installation, operation, and maintenance, with technical specifications and diagrams. The manual emphasizes safety and efficiency, making it a valuable resource for both professionals and DIY enthusiasts. Its structured approach ensures that all aspects of SVZ 18 maintenance are addressed thoroughly and effectively.

Safety Precautions for SVZ 18 Maintenance

Always prioritize safety by following guidelines in the manual. Handle refrigerants carefully, avoid hot water for filters, and ensure they’re installed to prevent damage.

General Safety Guidelines

Always follow safety guidelines when maintaining the SVZ 18. Ensure proper handling of refrigerants to avoid leaks or exposure. Never wash air filters in hot water, as this can damage them. Operate the unit only with filters installed to prevent internal damage. Use appropriate tools and equipment to avoid system malfunctions. Ensure the unit is powered off before performing any maintenance tasks. Proper installation and adherence to manufacturer instructions are crucial to prevent accidents. Regularly inspect the unit for wear or damage. Follow all safety precautions outlined in the manual to ensure safe and effective maintenance.

Handling Refrigerants Safely

When handling refrigerants for the SVZ 18, wear protective gloves and eyewear to avoid exposure. Use approved tools like gauges and flare tools to prevent leaks. Ensure the area is well-ventilated to avoid inhaling refrigerant vapors. Never mix refrigerants, as this can cause system damage. Follow proper charging and recovery procedures using a vacuum pump and recovery equipment. If a leak occurs, evacuate the area and contact a professional. Always dispose of refrigerants responsibly, adhering to environmental regulations; Proper training is essential for handling refrigerants safely and effectively, ensuring system performance and safety.

Electrical Safety Measures

Before performing any electrical work on the SVZ 18, disconnect the power supply to ensure safety. Use a multimeter to verify that no voltage is present. Avoid overloading circuits and ensure all connections are secure. Grounding systems must be properly installed to prevent electrical shocks. Regularly inspect wiring for damage or wear, and replace any faulty components immediately. Install circuit breakers or surge protectors to protect against power surges. Always follow local electrical codes and manufacturer guidelines. Keep emergency contact information handy in case of electrical emergencies. Proper adherence to these measures ensures a safe working environment and prevents potential hazards during maintenance tasks.

Maintenance Requirements for SVZ 18

Regular maintenance ensures the SVZ 18 operates efficiently and effectively. Key tasks include cleaning air filters, inspecting the outdoor unit, and checking refrigerant levels. Schedule routine checks to prevent system malfunctions and extend unit lifespan. Adhere to the recommended maintenance schedule outlined in the manual for optimal performance and reliability.

Recommended Maintenance Schedule

A well-structured maintenance schedule is crucial for the SVZ 18 system. Clean or replace air filters monthly to ensure proper airflow and efficiency. Inspect the outdoor unit quarterly for debris or damage. Annually, schedule a professional inspection to check refrigerant levels, coils, and electrical connections. Additionally, ensure the drain line is clear and functional to prevent water damage. Regularly cleaning the filters and maintaining the outdoor unit prevents system malfunctions. Adhering to this schedule ensures optimal performance, energy efficiency, and extends the lifespan of the unit. Always follow the manufacturer’s guidelines for specific maintenance tasks and timelines.

Cleaning the Air Filters

Cleaning the air filters of your SVZ 18 system is a simple yet critical maintenance task. Turn off the unit before removing the filters. Gently vacuum or brush off loose debris. For thorough cleaning, wash the filters with mild detergent and lukewarm water. Avoid using hot water (above 122°F/50°C), as it may warp the filters. Rinse thoroughly and allow them to dry completely before reinstalling. Regular cleaning ensures proper airflow, energy efficiency, and prevents system strain. Never operate the unit without the filters installed, as this can lead to reduced performance or damage. Clean filters monthly for optimal performance and system longevity.

Inspecting and Cleaning the Outdoor Unit

Regular inspection and cleaning of the SVZ 18 outdoor unit are vital for maintaining efficiency and preventing damage. Start by turning off the power supply. Inspect the condenser coils for dirt, debris, or bent fins, which can obstruct airflow. Use a soft brush or garden hose to gently remove dirt and debris. Avoid using harsh chemicals or high-pressure washes, as they may damage the coils. Check for any blockages in the drain and ensure proper water flow. Also, inspect the fan motor and blades for wear or damage. Clean the outdoor unit quarterly or more frequently if exposed to dusty or polluted environments. This helps maintain optimal performance and extends the system’s lifespan, ensuring reliable operation during extreme weather conditions while minimizing energy consumption and potential repairs.

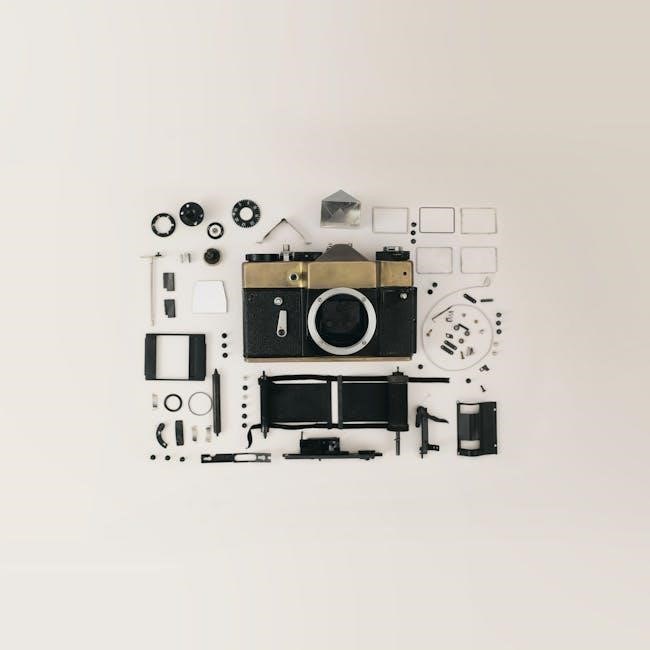

Tools and Materials Needed for Maintenance

Essential tools include a gauge manifold, flare tool, and vacuum pump for refrigerant handling. Materials like replacement filters, refrigerant, and sealants are also required for proper maintenance.

Basic Tools Required

For SVZ 18 maintenance, basic tools include screwdrivers, pliers, wrenches, and a multimeter. These tools are essential for tasks like tightening connections, checking electrical circuits, and ensuring proper system operation. A torque wrench is necessary for securing refrigerant lines and other components. Safety gear, such as gloves and goggles, should always be worn. Additionally, a vacuum pump and manifold gauge set are crucial for handling refrigerant safely. These tools help technicians perform routine checks, diagnose issues, and ensure the system runs efficiently. Always refer to the manual for specific tool recommendations to avoid damage or safety risks during maintenance procedures.

Specialized Tools for SVZ 18

Specialized tools for SVZ 18 maintenance include a refrigerant leak detector and a charging scale for handling R-410A refrigerant. A pressure test kit ensures proper system pressure, while a vacuum pump evacuates air and moisture. A programmable controller or remote is needed for advanced settings. These tools are vital for maintaining efficiency and safety, ensuring precise adjustments and preventing potential issues. Always use authorized tools to avoid system damage and maintain warranty compliance. Proper use of these tools requires training and adherence to safety protocols outlined in the manual.

Maintenance Materials and Supplies

Regular maintenance of the SVZ 18 requires specific materials and supplies to ensure optimal performance. Air filters should be replaced or cleaned with mild detergent and soft brushes. Insulation materials and sealants are essential for preventing refrigerant leaks and maintaining proper system pressure. A drain pan and condenser coil cleaner are necessary for efficient water drainage and coil maintenance. Lubricants for moving parts and protective coatings for outdoor units are also recommended. Always use materials compatible with R-410A refrigerant to avoid system damage. Safety gear, such as gloves and goggles, should be on hand during maintenance. These supplies ensure the system runs efficiently and safely, adhering to the manual’s guidelines.

Step-by-Step Maintenance Process

Begin with pre-maintenance checks, ensuring all safety protocols are followed. Perform routine tasks like cleaning filters and inspecting units. Conclude with post-maintenance verification to ensure system efficiency and reliability.

Pre-Maintenance Checks

Before starting maintenance, ensure the unit is powered off and disconnected from the power source. Verify that all capacitors and components are discharged to prevent electrical shocks. Inspect the area around the unit for any obstructions or debris that may interfere with maintenance tasks. Check the refrigerant levels and ensure all connections are secure. Review the manual to confirm the correct tools and materials are available. Ensure proper ventilation in the workspace to avoid exposure to refrigerants. Familiarize yourself with the unit’s controls and safety features to avoid accidental start-ups during maintenance. Always follow safety guidelines outlined in the manual.

Performing Routine Maintenance Tasks

Begin by cleaning or replacing the air filters to ensure proper airflow and efficiency. Inspect the outdoor unit for dirt or debris and clean it if necessary. Check the refrigerant lines for leaks or damage and ensure all connections are secure. Drain the condensate water properly to prevent moisture buildup. Use a vacuum pump to remove any air or moisture from the refrigerant system. Lubricate moving parts, such as fans and motors, to reduce wear and tear. Verify the electrical connections and contacts are clean and tight. Finally, use specialized tools to check and recharge refrigerant levels if needed, following safety guidelines.

Post-Maintenance Verification

After completing routine maintenance tasks, verify the system’s performance by running a test cycle. Ensure the unit operates smoothly, with no unusual noises or vibrations. Check for any leaks in refrigerant lines or drainpipes. Measure the system’s cooling and heating output to confirm it meets specifications. Verify that all safety features, such as emergency shutdowns, are functioning correctly. Inspect the air filters to ensure proper installation. Review the maintenance checklist to confirm all tasks are completed. Finally, record the maintenance details, including the date and any parts replaced, for future reference and to track the unit’s maintenance history.

Troubleshooting Common Issues

The manual provides detailed troubleshooting guides to address common problems, such as system malfunctions or error codes, helping users identify and resolve issues efficiently.

Identifying Common Problems

Common issues with the SVZ 18 include error codes, system malfunctions, and reduced performance. Users may encounter problems like refrigerant leaks, faulty sensors, or clogged air filters. The manual provides a list of error codes and their meanings, helping users identify the root cause of issues. For example, error codes like E1 or E2 may indicate sensor malfunctions, while E3 could signal a refrigerant leak. Additionally, unusual noises, uneven cooling, or water leakage are signs of potential problems. Regular checks and maintenance can help prevent these issues. The manual also offers step-by-step guidance to diagnose and address these problems effectively, ensuring optimal system performance.

Diagnosing System Malfunctions

Diagnosing system malfunctions in the SVZ 18 involves identifying error codes and performing systematic checks. Start by reviewing the error code list in the manual, as codes like E1, E2, or E3 indicate specific issues. Check sensors, refrigerant levels, and electrical connections for faults. Use a multimeter to test voltage and resistance, and inspect for leaks or blockages. Verify airflow and filter condition, as restricted airflow can trigger malfunctions. The manual provides detailed diagnostic procedures, including visual inspections and functional tests. Addressing issues promptly prevents further damage and ensures reliable operation. Always refer to the troubleshooting section for guidance tailored to the SVZ 18 model.

Resetting the System

Resetting the SVZ 18 system is a straightforward process to restore normal operation after minor malfunctions. First, switch off the unit using the remote controller or power button. Wait for 3-5 minutes to allow the system to fully power down. Then, restart the unit and check if the issue persists. If the problem remains unresolved, consult the troubleshooting section of the manual for specific guidance. Resetting ensures the system recalibrates and resumes efficient performance. Regular resets can prevent prolonged downtime and maintain optimal functionality. Always follow the manual’s instructions for safe and effective system resetting.

Repair and Replacement Guidelines

The SVZ 18 manual provides clear guidelines for repairs and replacements, ensuring safe and efficient servicing. It outlines when to replace parts, DIY repair tips, and when professional intervention is necessary.

When to Replace Parts

Replace parts when they show signs of wear or failure, such as reduced performance, unusual noises, or leaks. The manual recommends replacing air filters every 1-3 months and checking refrigerant levels annually. Coils should be inspected yearly and cleaned as needed. If components like compressors or fans malfunction, they must be replaced promptly to avoid system damage. Always use genuine parts to ensure compatibility and efficiency. Consult the manual or a professional if unsure about replacement procedures to maintain warranty validity and system reliability.

DIY Repair Tips

For minor issues, DIY repairs can save time and money. Start by cleaning or replacing air filters, as dirty filters are a common cause of reduced performance. Check for blockages in the drain pipe and ensure all vents are unobstructed. If the unit isn’t cooling, verify refrigerant levels and look for leaks. Restarting the system after a power outage often resolves operational hiccups. Always turn off power before attempting repairs. For more complex problems, consult the manual for guidance. Simple fixes like tightening loose connections or replacing worn-out seals can prevent major breakdowns. DIY repairs are cost-effective and extend the unit’s lifespan when done correctly.

When to Call a Professional

If you encounter complex issues like refrigerant leaks, electrical faults, or system malfunctions, it’s best to call a licensed technician. DIY repairs may not address deep-rooted problems, risking further damage or safety hazards. For tasks requiring specialized tools, such as handling refrigerants or diagnosing internal component failures, professional expertise is essential. Additionally, if you’re unsure about troubleshooting steps or lack experience with HVAC systems, consulting a professional ensures safe and effective repairs. Always prioritize safety and system integrity by seeking help when needed, as outlined in the manual’s guidelines for handling advanced maintenance and repairs.

Understanding the SVZ 18 Manual

The SVZ 18 manual provides clear instructions for installation, operation, and maintenance. It includes troubleshooting guides, technical specifications, and safety precautions, ensuring safe and efficient use of the unit.

Locating the Manual

The SVZ 18 maintenance manual can be easily accessed online through Mitsubishi Electric’s official website or reputable sources like ManualsLib; Users can search using the model number, SVZ-KP18NA, to find the latest version. Additionally, the manual is often provided with the unit at purchase. For digital convenience, it can be downloaded in PDF format, ensuring accessibility on various devices. Always verify the source to ensure authenticity and avoid outdated information. This ensures users have accurate guidance for maintenance, troubleshooting, and operation, promoting safe and effective use of the SVZ 18 air conditioner.

Navigating the Manual

The SVZ 18 maintenance manual is structured for easy navigation, starting with a detailed table of contents. It is divided into clear sections, including installation, maintenance, and troubleshooting. Key sections cover routine procedures, technical specifications, and safety guidelines. The manual includes diagrams and charts to aid understanding. Users can quickly locate specific information by referring to the model number or feature. A dedicated troubleshooting section helps identify and resolve common issues efficiently. The manual also highlights essential safety precautions and provides step-by-step instructions for complex tasks. This organized approach ensures users can find the information they need swiftly and effectively, making maintenance straightforward and stress-free;

Interpreting Technical Specifications

The SVZ 18 manual provides detailed technical specifications to ensure proper installation and operation. Key specifications include cooling and heating capacities, input power requirements, and external static pressure levels. The manual outlines airflow rates and sound pressure levels, helping users understand performance expectations. Diagrams and charts illustrate refrigerant flow and electrical connections. Technical terms are clearly defined, and measurement units are standardized for consistency. Users can cross-reference model numbers with specific performance metrics to verify compatibility. This section is crucial for technicians and installers to ensure the system operates within designed parameters, maximizing efficiency and reliability. Proper interpretation of these specs ensures optimal unit performance and longevity.

Environmental and Disposal Considerations

Proper disposal of the SVZ 18 unit is essential for environmental protection. Always consult a licensed dealer to ensure compliance with local regulations. Do not wash filters in hot water, as this may damage them. Environmental compliance and responsible recycling practices are emphasized to minimize ecological impact.

Proper Disposal of the Unit

Consult a licensed dealer for the proper disposal of the SVZ 18 unit to ensure environmental compliance. Do not dispose of the unit in regular waste, as it contains refrigerants and other hazardous materials. Improper disposal can lead to environmental contamination and legal penalties. Always follow local regulations and guidelines for recycling and safe disposal. The manufacturer emphasizes responsible disposal practices to minimize ecological impact. Properly handling the unit at the end of its lifecycle is crucial for sustainability. Ensure all refrigerants are safely recovered and components are recycled according to industry standards. This approach aligns with Mitsubishi Electric’s commitment to environmental stewardship and responsible product management.

Recycling Guidelines

Recycling the SVZ 18 unit involves adhering to local and manufacturer guidelines to ensure environmentally responsible disposal. Separate recyclable materials like metals and plastics from hazardous components. Refrigerants must be safely extracted by licensed professionals to prevent environmental harm. Check with local recycling programs or Mitsubishi Electric authorized dealers for proper procedures. Units should be dismantled to recycle parts, reducing landfill waste. Follow all applicable regulations to ensure compliance with environmental standards. Proper recycling helps conserve resources and aligns with Mitsubishi Electric’s commitment to sustainability. Always prioritize eco-friendly disposal methods to minimize the unit’s environmental footprint.

Environmental Compliance

Environmental compliance is crucial when handling the SVZ 18 unit, ensuring adherence to local and international regulations. Proper disposal and recycling practices prevent hazardous materials from harming the environment. Refrigerants must be handled in accordance with safety protocols to avoid ozone depletion and greenhouse gas emissions. Mitsubishi Electric recommends working with authorized dealers to ensure compliance with environmental standards. Regular maintenance and eco-friendly practices contribute to sustainability. Always follow manufacturer guidelines for waste disposal and energy efficiency. Compliance not only protects the environment but also aligns with global efforts to reduce carbon footprints and promote sustainable technologies.

Additional Resources and Support

For further assistance, download the SVZ 18 manual from Mitsubishi Electric’s official website or authorized dealers. Contact customer support for personalized help and troubleshooting. Online forums also offer valuable insights and user experiences.

Downloading the Manual

To access the SVZ 18 maintenance manual, visit Mitsubishi Electric’s official website or authorized dealer platforms. Use the model number SVZ-KP18NA in the search bar for quick retrieval. Alternatively, search engines like Google can be used with keywords such as “SVZ-KP18NA maintenance manual PDF” to find digital versions. Ensure the manual is downloaded from reputable sources to avoid outdated or incorrect information. The manual is specifically designed for the SVZ-KP18NA model, providing detailed maintenance procedures, troubleshooting guides, and safety protocols. Always verify the source for authenticity before downloading to ensure reliability and safety.

Customer Support Contact Information

For assistance with the SVZ 18, contact Mitsubishi Electric’s customer support team. Visit their official website for regional contact details, or call their dedicated support line at 1-800-MITSUBISHI. Email inquiries can be sent to mebsupport@meus.mitsubishielectric.com. Additionally, live chat options are available on their website for immediate help. Ensure to have your unit’s model number, SVZ-KP18NA, ready for faster service. Mitsubishi Electric’s support team is available to address installation, maintenance, and repair queries, ensuring your system operates efficiently. Their knowledgeable staff will guide you through troubleshooting or connect you with certified technicians if needed.

Online Communities and Forums

Active online communities and forums provide valuable support for SVZ 18 users. Platforms like HVAC-Talk and Reddit’s home improvement communities offer peer-to-peer advice and troubleshooting tips. Mitsubishi Electric’s official forums also host discussions, allowing users to share experiences and solutions. These spaces are ideal for addressing specific issues or seeking DIY repair guidance. Additionally, websites like ManualsLib and industry-specific forums often feature detailed discussions about the SVZ-KP18NA model. Engaging with these communities can provide insights and tricks for maintaining your unit efficiently. They complement the official manual, offering real-world perspectives and collective expertise to enhance your maintenance routine.

The SVZ 18 maintenance manual is a vital resource for ensuring optimal performance and longevity. Regular maintenance, adhering to safety guidelines, and utilizing troubleshooting tips will maximize efficiency and reliability.

Summarizing Key Maintenance Points

Regular maintenance is crucial for the SVZ 18’s optimal performance and longevity. Key tasks include cleaning air filters, inspecting the outdoor unit, and ensuring proper refrigerant handling. Always follow safety guidelines, such as disconnecting power before servicing and using appropriate tools. Refer to the manual for detailed schedules and procedures. Proper disposal of materials and adherence to environmental guidelines are also essential. By following these steps, users can ensure efficient operation, reduce energy consumption, and extend the unit’s lifespan. Regular checks and timely repairs will prevent major issues, ensuring reliable cooling and heating performance throughout the year.

Encouraging Regular Maintenance

Regular maintenance is vital for the SVZ 18 to function efficiently and reliably. It prevents breakdowns, reduces energy costs, and extends the unit’s lifespan. By adhering to the recommended schedule, users can ensure consistent performance and maintain indoor air quality; Cleaning filters, inspecting components, and addressing issues promptly are simple yet effective practices. The manual provides clear guidelines, making it easy for users to stay on track. Encouraging a proactive approach to maintenance not only safeguards the system but also enhances overall comfort and satisfaction. Consistent upkeep ensures the SVZ 18 operates at its best, providing reliable cooling and heating year-round.

Final Thoughts on SVZ 18 Maintenance

Proper maintenance of the SVZ 18 is essential for maximizing its performance, efficiency, and lifespan. By following the manual’s guidelines, users can ensure consistent cooling and heating while reducing energy consumption and potential repair costs; Regular tasks like cleaning filters and inspecting components are critical for maintaining optimal functionality. Consistent upkeep not only prevents unexpected breakdowns but also enhances indoor air quality and overall comfort. For long-term reliability, adhering to the recommended maintenance schedule is key. Always refer to the manual for specific instructions, and address any issues promptly to keep the SVZ 18 operating at its best.